ESD PROTECTIVE SOLUTIONS

PROTECTING ELECTRONICS THROUGHOUT THE SUPPLY CHAIN

ESD CONTAINERS ARE IDEAL FOR ELECTRONICS,

TELECOMMUNICATIONS, AND COMPUTERS

What is ESD?

Electrostatic Discharge (ESD) transfers a finite amount of charge between two bodies at different potentials. Discharges from external sources like humans and equipment or induced electrostatic fields can damage ESD sensitive parts. ESD-safe containers protect integrated circuit (IC) products, including circuit boards and other electronics in the automotive supply chain from being damaged through electrostatic discharge. Utilizing ESD products will protect the most sensitive components from static charge that occurs during manufacturing, assembly, and shipping of electronic devices. Common parts that use ESD-safe packaging include USBs, circuit boards, video outputs, 12-V DC systems, RF outputs, LED lighting, and other electronics

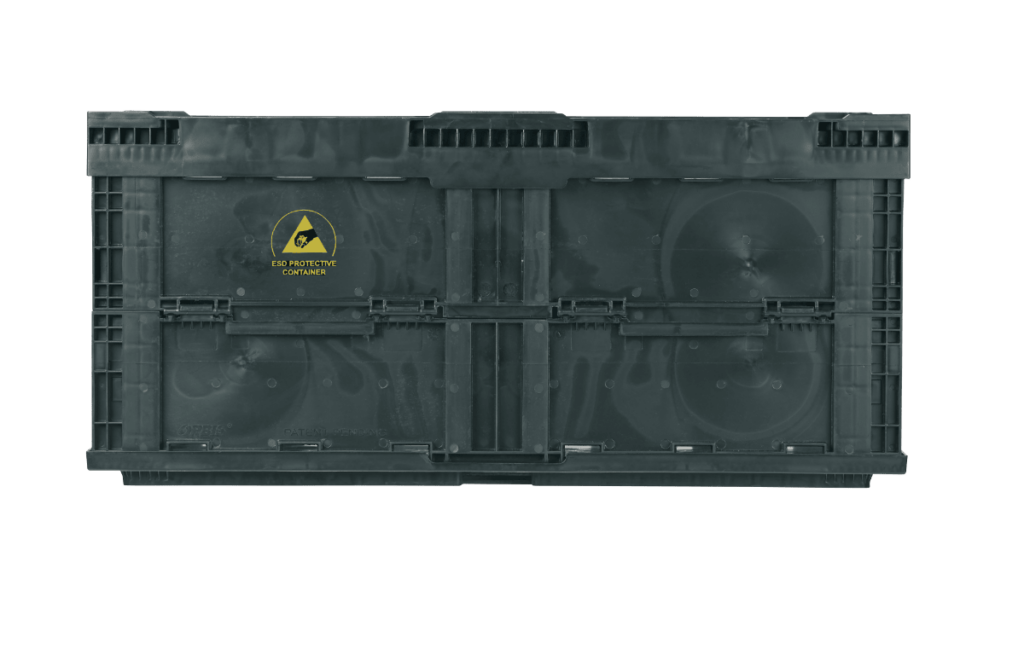

ESD-safe containers will have a

“ESD Protective Container” logo

on each container

How can you protect against ESD?

ORBIS helps customers protect sensitive electronic parts from static

discharge. ESD-safe material will transfer the charge through the

container, keeping your products safe during transportation. The two

primary materials used are conductive and static dissipative material.

The electrical properties of this material are permanent and unaffected

by washing. ESD-safe material is available in all ORBIS StakPak® and

Hand Held Folding Containers. Standard sizes are available in both AIAG

and metric footprints and are compatible with ESD-safe lids.

RCSO2415-1 lid on NXO2415-11.5

HHFC2415-11

ESD Reference Guide

Resistance Classification taken from ANSI-ESD S541

Insulative: ORBIS Standard Offering

Insulative materials have a surface resistance of ≥10¹¹ Ohms. The more resistant a material is, the faster a current will flow across

the material. Insulative materials discharge slower than most static charges are created. This allows a charge to build up over time,

making this material unsuitable for ESD needs.

Conductive vs. Static Dissipative

Conductive materials have a surface resistance of < 10⁴ Ohms. This material quickly displaces the charge, helping to protect direct discharges from reaching sensitive products. Static dissipative materials have a surface resistance of ≥10⁴ to <10¹¹ Ohms. This material displaces charge slower than conductive materials. Both conductive and static dissipative materials help drain existing charges away from products. Dissipative materials help protect against charged device model (CDM) damage. If a sensitive device or circuit board becomes charged, dissipative material will slowly control the discharge to protect the product. These permanent and reusable solutions help protect electronics throughout the supply chain. For more information on ESD materials, please contact your ORBIS sales representative.

Rely on ORBIS® for custom protective dunnage from its ORBIShield® line to protect parts during transit, assembly, and storage. The long-term implementation of ORBIShield® dunnage improves inventory control by maintaining consistent quantities in each container and optimizes lineside efficiency by facilitating better part presentation. Using all types of foam, sheet, and fabric materials and state-of-the-art technology, ORBIS® is your single-source leader in reusable dunnage.

ORBIS offers customized part protection with ORBIShield® protective dunnage

ESD-SAFE PROTECTIVE DUNNAGE:

Download our ESD Capabilities PDF